Standard: ASME SB575

Other Standard: GB, AISI, ASTM/ASME, DIN, EN, JIS

Shapes: Plates/ Sheets

Width: 0mm ~ 2500mm

Surface Treatment(Finish): Mirror, Brushed, Mill Finished, Polished, Pickling,Pickling + sandblasting

Standard: ASME SB575

Other Standard: GB, AISI, ASTM/ASME, DIN, EN, JIS

Shapes: Plates/ Sheets

Width: 0mm ~ 2500mm

Surface Treatment(Finish): Mirror, Brushed, Mill Finished, Polished, Pickling,Pickling + sandblasting

| Hastelloy | Density (g/cm3) | Melting point (℃) | Elongation A5 (%) | Tensile Strength (Rm N/mm2) | Yield Strength (RP0.2N/mm2) | Rockwell Hardness |

| C-2000 | 8.5 | 1357-1385℃ | 45 | 690 | 310 | 88-100HRB |

Type: Cold finished(cold rolled), Hot finished( Hot rolled)

Thickness of Plates: 4.76mm ~ 60mm (Hot Rolled), Width: 0mm ~ 2500mm

Thickness of Sheet: 1.00mm ~ 4.76mm (Cold Rolled), Width: 0mm ~ 1500mm

Surface Treatment(Finish): Mirror, Brushed, Mill Finished, Polished, Pickling,Pickling + sandblasting

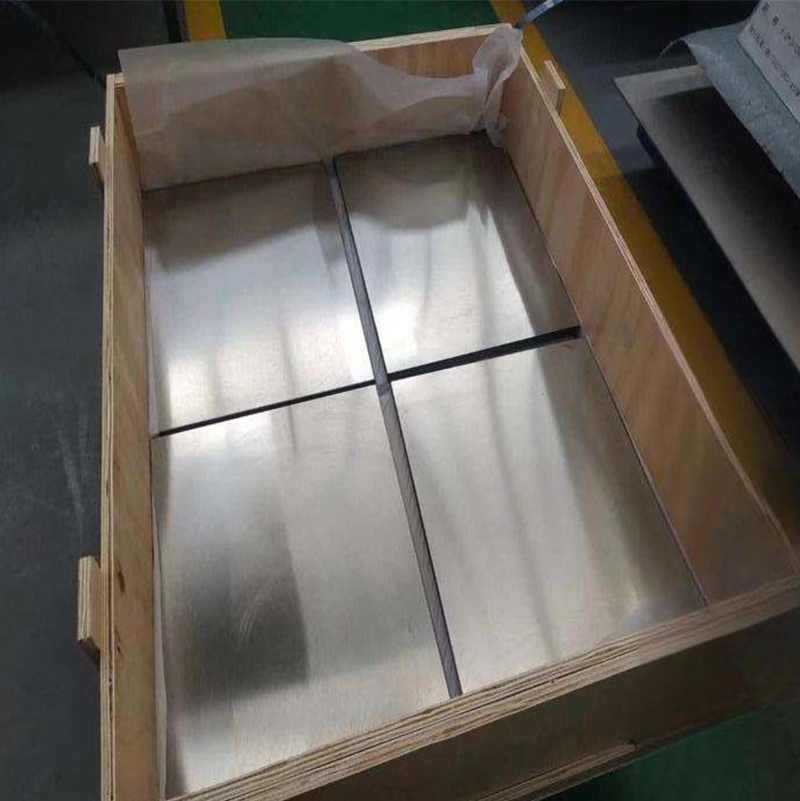

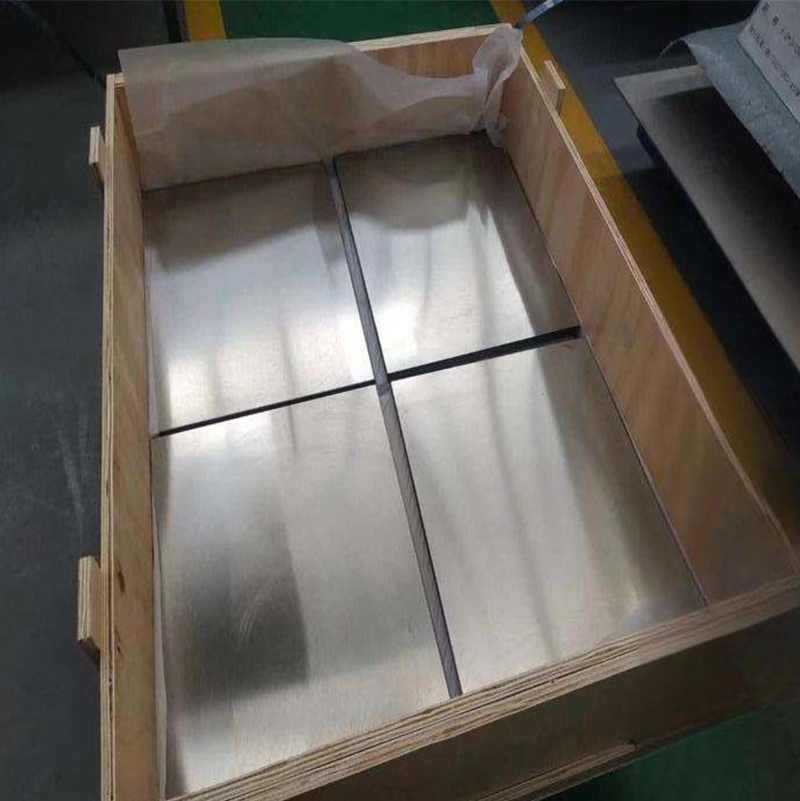

Edge:Grinding, cutting

Melting method: Vacuum Induction Melting (VIM) + Electroslag Remelting (ESR); or VIM + VAR

Inspection: TUV, SGS,

Packing: Wooden box, Waterproof polybag

Application:

Hastelloy C-2000 is a versatile nickel alloy used where both oxidizing and reducing acids are present. Its main applications are:

Chemical Processing

Equipment for sulfuric acid (all concentrations, especially when contaminated).Systems handling hydrochloric acid with oxidizers and aggressive mixed acids.

Pollution Control

Critical components in Flue Gas Desulfurization (FGD) scrubbers and wastewater treatment.

Pharmaceutical & Fine Chemical Plants

Reactors and piping for processes using chlorine, bromine, or acetic acid.

Pulp & Paper Industry

Bleach plant equipment exposed to hot, acidic chlorinated chemicals.

In short: It is the “all-rounder” alloy for handling complex, changing, or contaminated acid environments, especially sulfuric and mixed acids.