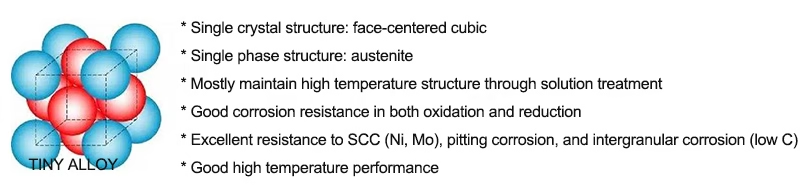

Hastelloy alloy is a general term for the commercial grades of nickel-based corrosion-resistant alloys produced by Hastelloy International, USA. It is mainly divided into two categories: nickel-chromium alloy and nickel-chromium-molybdenum alloy.

Hastelloy alloy include the following grades:

HASTELLOY B-2 Nickel-molybdenum alloy, with excellent corrosion resistance in reducing environments

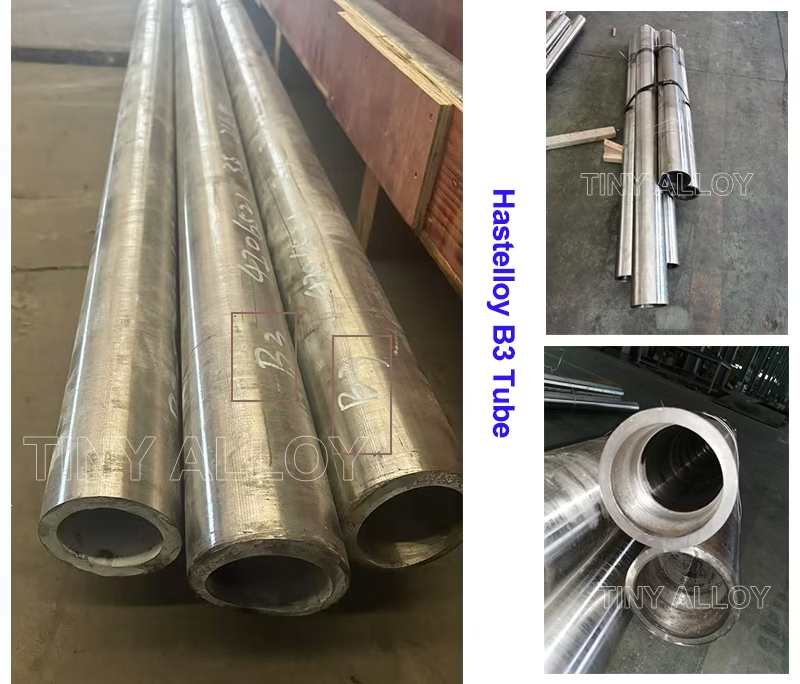

HASTELLOY B-3 An upgraded version of B-2 with excellent corrosion resistance to hydrochloric acid at any temperature and concentration.

HASTELLOY C-4 has good thermal stability, 650-1040 degrees Celsius, and toughness and corrosion resistance.

HASTELLOY C-22 has better uniform corrosion resistance in oxidizing media than C-4 and C-276 and excellent local corrosion resistance

HASTELLOY C-276 has good resistance to oxidizing, moderate reducing corrosion, and excellent stress corrosion resistance.

HASTELLOY C-2000: The most comprehensive corrosion-resistant alloy with excellent uniform corrosion resistance in oxidizing and reducing environments.

HASTELLOY G-35 is an upgraded product of G-30, with better corrosion resistance and thermal stability. HASTELLOY G-30 is a high-chromium nickel-based alloy that performs well in phosphoric acid and other strong oxidizing mixed acid media.

HASTELLOY X combines high strength, oxidation resistance, and easy processing

Each of the above grades has a specific chemical composition, mechanical properties, and strengths. It is not possible to generalize the characteristics of Hastelloy. Its good corrosion resistance and thermal stability are widely used in the following fields: heat exchangers, bellows compensators, chemical equipment, flue gas desulfurization and denitrification, the papermaking industry, aerospace applications, and acidic environments.