Among nickel-based alloys, Monel 400 (UNS N04400), with its high-strength, single-phase solid-solution structure, is the most widely used corrosion-resistant alloy, offering excellent overall performance. However, these performance advantages are matched by significant challenges in its manufacturing process.

Monel 400 produced using traditional processes often faces the following issues:

01, Internal defects are challenging to control

Due to the alloy’s lower liquidus temperature compared to other nickel alloys and its susceptibility to gas absorption, problems such as unstable melting rates and slag inclusion are highly likely to occur during the electroslag remelting (ESR) process. This leads to defects such as intermittent porosity and segregation in the forgings, resulting in erratic ultrasonic testing (UT) yields.

02, Severe surface oxidation and wear

Monel 400’s susceptibility to gas absorption and the high hot working temperatures result in significant surface oxidation. The resulting thick oxide layer significantly increases subsequent machining costs and material loss.

03, Low overall yield

These internal and surface defects drive down final product yield, increasing total production costs.

Our Tiny Alloy’s technical team has re-engineered the production of Monel 400 with three targeted process innovations:

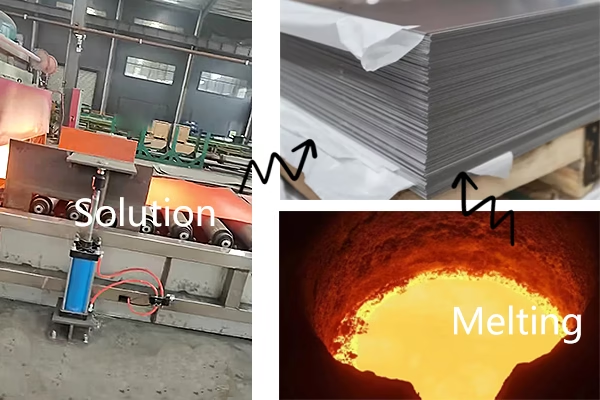

1, Optimized Electroslag Remelting (ESR):

We increased the melting rate and operating voltage to enhance ingot solidification. This refinement significantly improves internal density and minimizes defects like porosity and segregation at their source.

2, Reduced Forging Temperature:

The forging temperature has been systematically lowered from 1130°C to 1060°C. This effectively suppresses gas absorption and oxidation, leading to a superior surface condition.

3, Increased Forging Ratio:

By raising the forging ratio from 6 to over 10, we achieve greater plastic deformation. This process welds internal micro-defects, refines the grain structure, and enhances the overall uniformity and integrity of the material.

These process upgrades deliver measurable outcomes:

1, Superior Internal Quality: The billets now consistently pass the stringent Ultrasonic Testing (UT) requirements of ASTM A338, ensuring high and reliable UT pass rates.

2, Improved Surface Quality: The surface oxide layer has been reduced from 0.55mm to 0.35mm, drastically decreasing machining allowances and material waste for our customers.

3, Greater Cost Efficiency: These improvements collectively lower machining costs and time while increasing the final product yield and reliability.

Tiny Alloy is committed to delivering not only materials but also reliable solutions. Through continuous technological innovation, we transform industry challenges into our quality advantages, ensuring that every batch of Monel 400 material received by users has excellent performance and stable quality.