| Hastelloy |

Density (g/cm3) |

Melting point (℃) |

Elongation A5 (%) |

Tensile Strength (Rm N/mm2) |

Yield Strength (RP0.2N/mm2) |

Rockwell Hardness |

| B-3 |

9.22 |

1370-1418℃ |

40 |

760 |

350 |

85-100 HRB |

Type: Cold finished(cold rolled), Hot finished(Hot Forged or Hot rolled)

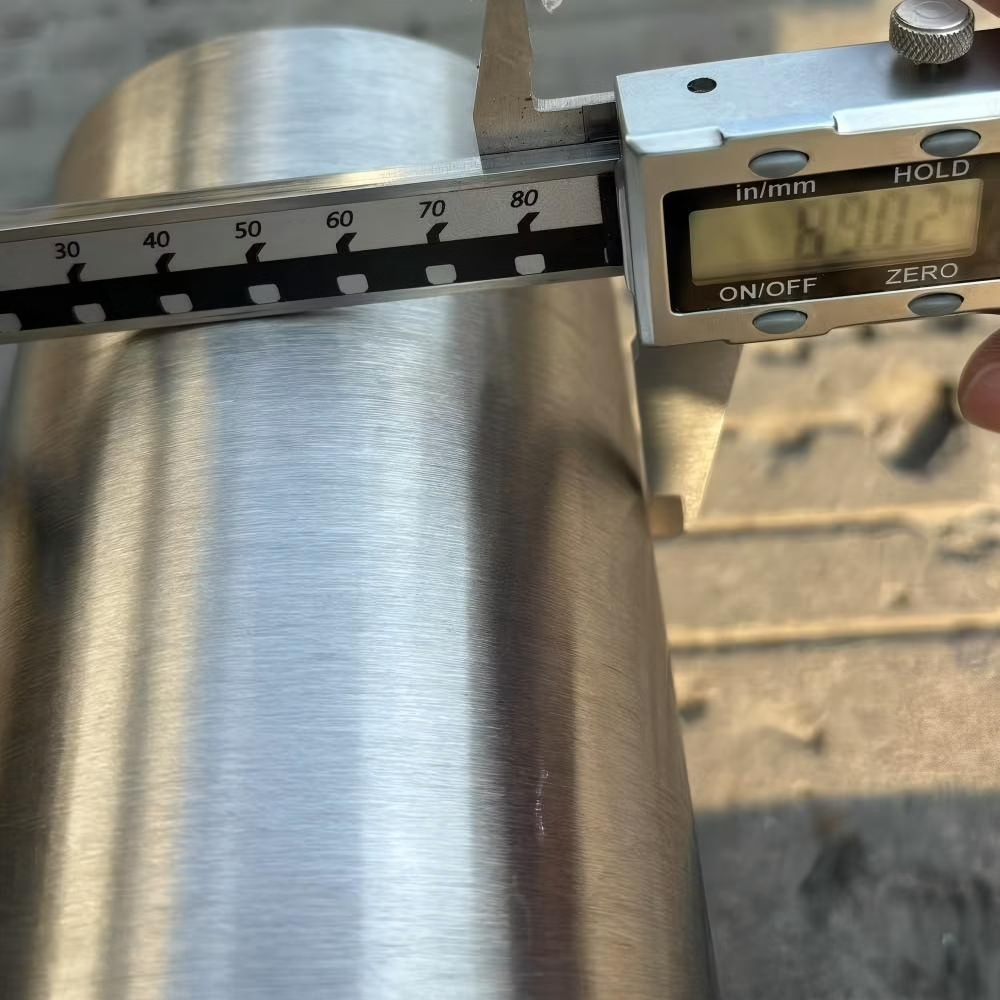

Shape: Round

Standard: GB, AISI, ASTM/ASME, DIN, EN, JIS

Diameter: 6mm – 400mm

Finish: Bright, Pickling, Black, Polished, Peeling

Inspection: TUV, SGS,

Melting method: Vacuum Induction Melting (VIM) + Electroslag Remelting (ESR)

Packing: Wooden box, Waterproof polybag

Processing Service: Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining

Deformation processing : Bending / Cutting / Rolling / Stamping

Forged

Application:

Hastelloy B3 is a nickel-molybdenum (Ni-Mo) based high-temperature alloy. Compared to the earlier B2 alloy, its optimized composition (e.g., added chromium and tungsten) significantly improves thermal stability and resistance to intergranular corrosion, making it particularly suitable for highly reducing acid environments. Below are its key applications and characteristics:

A. Primary Application Areas

1. Chemical & Petrochemical Industry

Strong Acid Environments:

Reactors, pipelines, and valves for media such as hydrochloric acid (HCl), sulfuric acid (H₂SO₄), and phosphoric acid (H₃PO₄).

Especially suitable for high-temperature concentrated hydrochloric acid (e.g., ≥20% concentration, ≤100°C).

Organic Synthesis:

Equipment for producing organic acids, such as acetic acid and formic acid.

2. Pharmaceutical & Electroplating

Liquid Delivery Systems: Resists corrosion from chloride ion (Cl⁻)-containing pharmaceutical solutions.

Electroplating Tanks & Heaters: Withstands aggressive plating solutions (e.g., acidic chloride baths).

3. Environmental Protection & Hydrometallurgy

Waste Acid Recovery Systems: Heat exchangers in hydrochloric acid regeneration units.

Flue Gas Desulfurization (FGD): Components in high-chloride scrubber systems.

4. Nuclear Industry

Containers or piping for highly reducing acid media in nuclear fuel reprocessing.

B. Key Performance Advantages

Corrosion Resistance Far superior to stainless steel in reducing acids (e.g., HCl, H₂SO₄), even outperforming B2 alloy (reduced grain boundary precipitation).

Thermal Stability Resists harmful phase formation (e.g., μ-phase) at high temperatures; long-term service up to 400°C.

Stress Corrosion Cracking (SCC) Resistance: Exceptional resistance to chloride-induced SCC.

Fabrication Weldable (using matching filler like ERNiMo-10), excellent hot/cold workability.

C. Limitations & Considerations

Not Suitable for Oxidizing Environments:

Rapid corrosion occurs in nitric acid (HNO₃) or acidic solutions containing Fe³⁺/Cu²⁺; Hastelloy C-series (e.g., C276) is recommended for such cases.

Avoid High-Temperature Oxidation:

Prolonged exposure to air at temperatures of≥500°C causes degradation; use in inert atmospheres or under vacuum.

C. Typical Equipment Components

Chemical: Reactors, heat exchangers, pump casings, agitator shafts.

Electroplating: Anode baskets, heating coils.

Pharmaceutical: Crystallizers, distillation column internals.